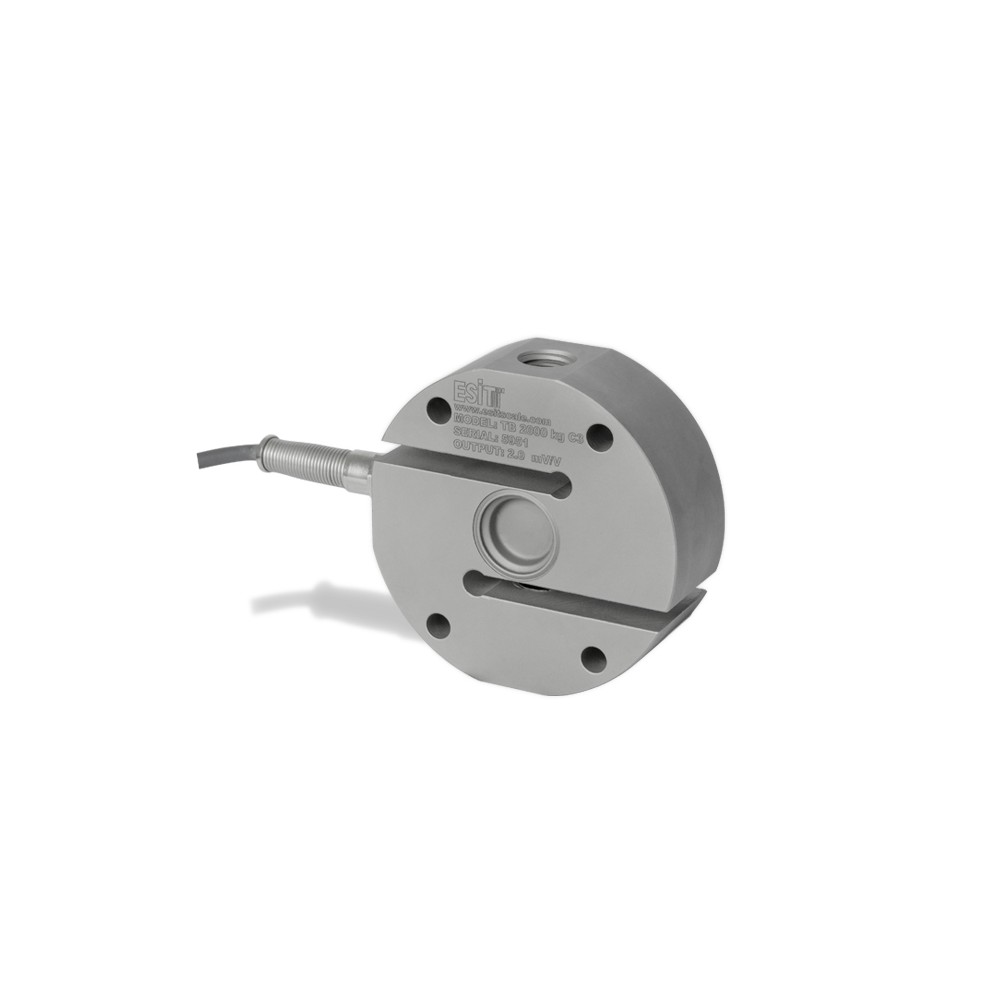

ESIT TB-3000 3000kg. S TYPE LOAD CELL

The TB S-type load cell has been developed for use in electronic weight and force measurement applications and is suitable for handling both tension and compression forces.

The TB load cell finds application in tank weighing applications, hopper scales, electro mechanical scales, tension-tear test devices, process weighing applications and other similar systems. With its stainless steel construction as well as its strain gauge area which is fully welded with a stainless steel cover, the TB load cells are protected to IP68 standards meaning that they are fully immersible.